Description

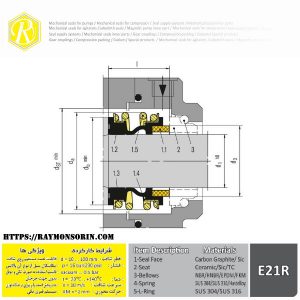

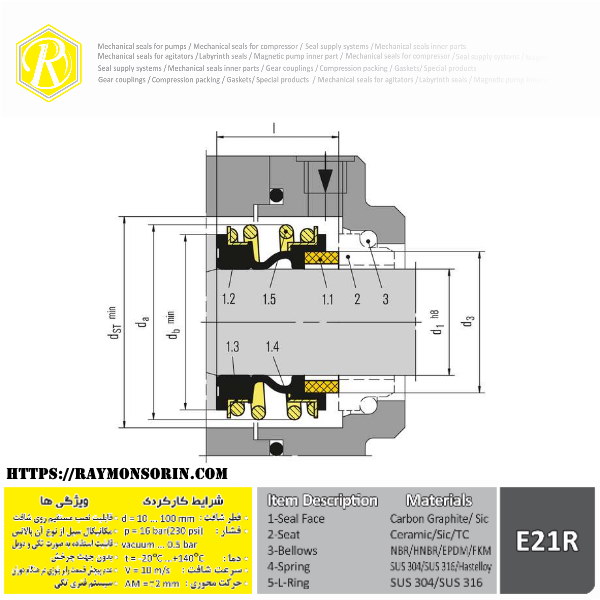

Elastomer Mechanical seals E21R

| ITEM | PART NO. TO DIN 24250 | DESCRIPTION |

| 1.1 | 472 | Seal face |

| 1.2 | 481 | Bellows |

| 1.3 | 484.2 | L-ring (spring collar) |

| 1.4 | 484.1 | L-ring (spring collar) |

| 1.5 | 477 | Spring |

| 2 | 475 | Seat |

| 3 | 412 | O-Ring or cup rubber |

Features

- For plain shafts

- Single and dual seal

- Elastomer bellows rotating

- Unbalanced

- Independent of direction of rotation

- No torsion on bellows

Advantages

- Shaft protection over entire seal length

- Protection of seal face during installation due to special bellows design

- Insensitive to shaft deflections due to large axial movement ability

- Universal application opportunities

- Important material certifications available

- High flexibility due to wide offer on materials

- Suitable for low-end sterile applications

- Dimension adaptions and additional seats available

Operating range

Shaft diameter: d1 = 10 … 100 mm (0.39″ … 3.94″)

Pressure: p1 = 16 bar (230 PSI), vacuum … 0.5 bar (7.25 PSI), up to 1 bar (14.5 PSI) with seat locking

Temperature: t = -20 °C … +140 °C (-4 °F … +284 °F)

Sliding velocity: vg = 10 m/s (33 ft/s)

Admissible axial movement: ±2.0 mm (±0,08″)

Pressure: p1 = 16 bar (230 PSI), vacuum … 0.5 bar (7.25 PSI), up to 1 bar (14.5 PSI) with seat locking

Temperature: t = -20 °C … +140 °C (-4 °F … +284 °F)

Sliding velocity: vg = 10 m/s (33 ft/s)

Admissible axial movement: ±2.0 mm (±0,08″)

Materials

Seal face: Carbon graphite antimony impregnated (A), Carbon graphite resin impregnated (B), Silicon carbide (Q1, eSiC-Q7)

Seat: Silicon carbide (Q1, eSic-Q7), Tungsten carbide (U3)

Elastomer: NBR (P), EPDM (E), FKM (V),

HNBR (X4)

Metal parts: CrNiMo steel (G), Hastelloy® (M)Further materials upon request.

Seat: Silicon carbide (Q1, eSic-Q7), Tungsten carbide (U3)

Elastomer: NBR (P), EPDM (E), FKM (V),

HNBR (X4)

Metal parts: CrNiMo steel (G), Hastelloy® (M)Further materials upon request.

Standards and approvals

- FDA

- WRAS

- KTW

- ACS

- W270

- NSF

Recommended applications

- Fresh water supply

- Building services engineering

- Waste water technology

- Food technology

- Sugar production

- Pulp and paper industry

- Oil industry

- Petrochemical industry

- Chemical industry

- Water, waste water, slurries

(solids up to 5 % by weight) - Pulp (up to 4 % otro)

- Latex

- Dairies, beverages

- Sulfide slurries

- Chemicals

- Oils

- Chemical standard pumps

- Helical screw pumps

- Stock pumps

- Circulating pumps

- Submersible pumps

- Water and waste water pumps

- Oil applications

Reviews

There are no reviews yet.